[Secrets of Development #8: Construction] First building to be completed among the signature pavilions—Realistic processes and the thoughts behind them

Based on the architectural concept and basic design of the Future of Life signature pavilion developed by the architectural team together with pavilion producer ISHIGURO Hiroshi’s team, the actual construction was carried out by the Haseko Group (HASEKO). This time, we spoke with EGUCHI Ryuichi and TONOMURA Yuji, who were responsible for the actual construction work in the pavilion’s construction management, as well as ONISHI Hiromi, who is a member of the Future of Housing Meeting organized by Ishiguro and HASEKO. Onishi was also project manager of the construction of the pavilion. They talked about the challenges and ingenuities in constructing the pavilion as well as their thoughts after its completion.

From simple sponsorship to in-kind sponsorship via design cooperation and construction

In the autumn of 2021, HASEKO decided early to sponsor the Future of Life theme project, but an immediate decision could not be made when Ishiguro sounded out about having HASEKO also undertake the construction. Looking back at this request, Onishi said, “Our main market was in the construction of multi-unit housing. We didn’t have any prior experience in constructing facilities like the pavilion. Various opinions were sought from the relevant departments within the company on technical, cost, and other aspects, and it took close to a year of study before we reached a decision.”

A decision was finally made in the autumn of 2022 to switch to in-kind sponsorship (sponsorship through the provision of services, technology, construction, and other such forms) via design cooperation and construction for the pavilion. The words of Ishiguro were significant in supporting this decision.

Onishi elaborated, “In parallel with the study on in-kind sponsorship, starting from the summer of 2022, we held the Future of Housing Meeting, a series of discussions about multi-unit housing (condominiums) of the future with Professor Ishiguro and the other members focusing on themes such as androids and condominiums, and lives and living. One day, after several sessions of the meeting had been held, Professor Ishiguro stated that he felt that HASEKO would be able to realize the pavilion’s construction as we shared the same thoughts. Sensing the professor’s strong desire, I felt a need to meet his expectations.”

After a period of preparation, Eguchi and Tonomura were appointed as on-site supervisors in June and November 2023 respectively. Both said they were very surprised.

Eguchi talked about his surprise back then, saying, “I was surprised because my experience so far had been centered on condominium construction, even though I had some experience in steel-framed construction.”

For Tonomura, “While I was surprised, I was also happy because I felt that I won’t be involved in such a project in the future. I told myself that I would do something that I would be proud of.”

Started by carefully talking to many stakeholders and sharing information

Based on the drawings created by the architectural team, Eguchi and Tonomura started by conducting detailed discussions with many stakeholders, including the production team, architectural team, exhibition team, Expo association, and exhibition setup operators.

Tonomura recalled, “There are many stakeholders, so it was important to find out in detail their respective requirements and make adjustments. How do we go about construction and finishing to get closer to each stakeholder’s requirements? We shared drawings and photographs with each other and made precise reconciliations. Regarding products used in construction, it is often difficult to understand without actually seeing them with our own eyes. Therefore, we gathered products from various places at around four to five plants in Japan, where we carried out material confirmation and inspection.”

Then, based on the design documents created by the architectural team, the processes required for construction were coordinated internally and implemented as one team by six persons in charge of construction management and two in charge of drawings for on-site operations as well as others from departments related to structure and technology, the environment, and administration. These processes included the signing of contracts with business operators, arrangements for operators, scheduling of construction processes, and carrying out building construction while undertaking safety management.

Using environmentally friendly concrete

“We were especially particular about adopting H-BA Concrete, an environmentally friendly concrete developed in-house by HASEKO. It reduces the amount of CO2 emissions during manufacturing yet has the same performance as ordinary concrete. Therefore, we thought it would be an appropriate material for this Expo, which emphasizes sustainability, and we passionately proposed it to the architectural team to obtain their support. It was a major challenge for HASEKO as there wasn’t much of a track record for using this concrete at that point in time before construction started,” said Eguchi.

Tonomura added, “As the venue is on reclaimed land, the design specifications called for the use of lightweight concrete in consideration of ground subsidence. It was thus also necessary to make H-BA Concrete lighter. It also became necessary to carry out construction confirmation, something that we had not even considered in the past, whereby, in each stage of construction, we measured the building and ground level at the corners of the building to confirm that uneven subsidence (where the building sinks in an uneven manner) was not occurring before we embarked on the next process.”

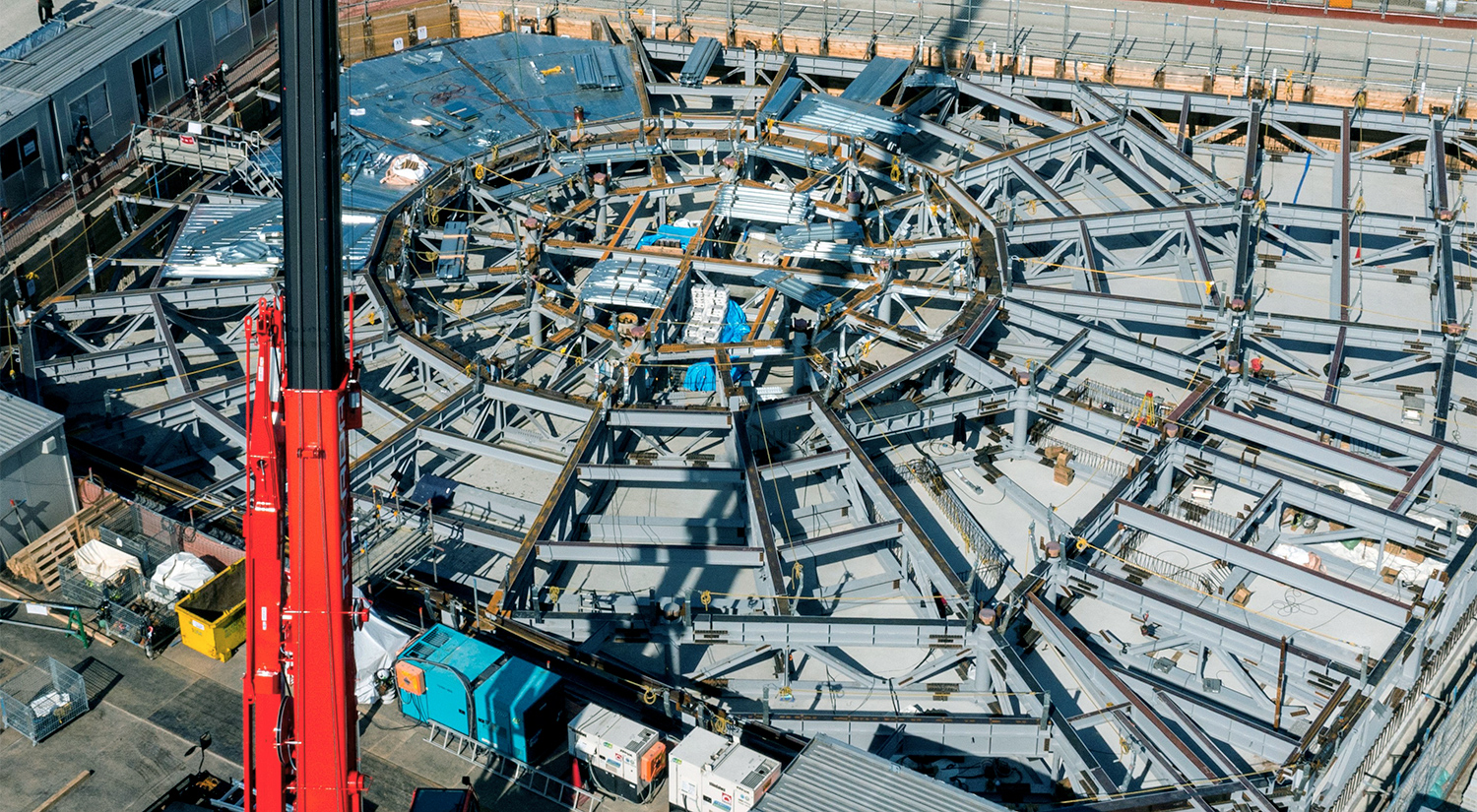

Many ideas were also implemented to achieve the pavilion’s spider web-like steel frame and its special shape, which seems to draw circles also in the vertical direction.

Tonomura said, “We checked the fit of the steel frame’s drawings many times using a 3D viewer. During construction, we also weighed each set of construction materials because a discrepancy of 1 mm can lead to a major overall discrepancy. We spent more time than usual on each task, striving to ensure greater construction accuracy.”

A lot of effort was also taken to work on the flow of water and waterproofing measures (measures to prevent water from entering buildings and other architectural structures).

Confronting the shortage of time and manpower with the power of ideas and cooperation

They also poured their hearts and souls into dealing with the issues of completing construction on time and a shortage of manpower, issues that were also faced by many other pavilions.

Tonomura explained, “We didn’t have much leeway in the number of days for construction. As such, we established a system where things that can be done off-site were followed up within the company, and we formulated a plan that allowed us to move forward with construction as quickly as possible. We were thorough in carrying out construction management within reason but without waste. In particular, we studied whether we could carry out exterior coating without setting up scaffolding. We adopted a plan where we used roads within the premises of the Expo’s venue and even borrowed the premises of adjacent pavilions to carry out tasks from aerial work platform vehicles. We consulted the Expo association and adjacent pavilions’ staff, coordinated with them, and received their cooperation, allowing us to shorten the construction period.”

“Many pavilions were waiting due to a shortage of manpower faced by the contractors. We tried to secure manpower from our existing connections, and when we had to wait because a certain process could only be done by a specific operator, we changed the construction sequence that was originally planned to first work on tasks that could be done by the current set of manpower, advancing the plan flexibly to deal with the situation. This approach proved successful, and we were able to complete construction on time,” added Eguchi.

First signature pavilion to be completed, drawing much reaction

Under the leadership of Eguchi and Tonomura, many detailed ideas were implemented to achieve the earliest building handover among the signature pavilions. This drew a series of happy responses from the stakeholders.

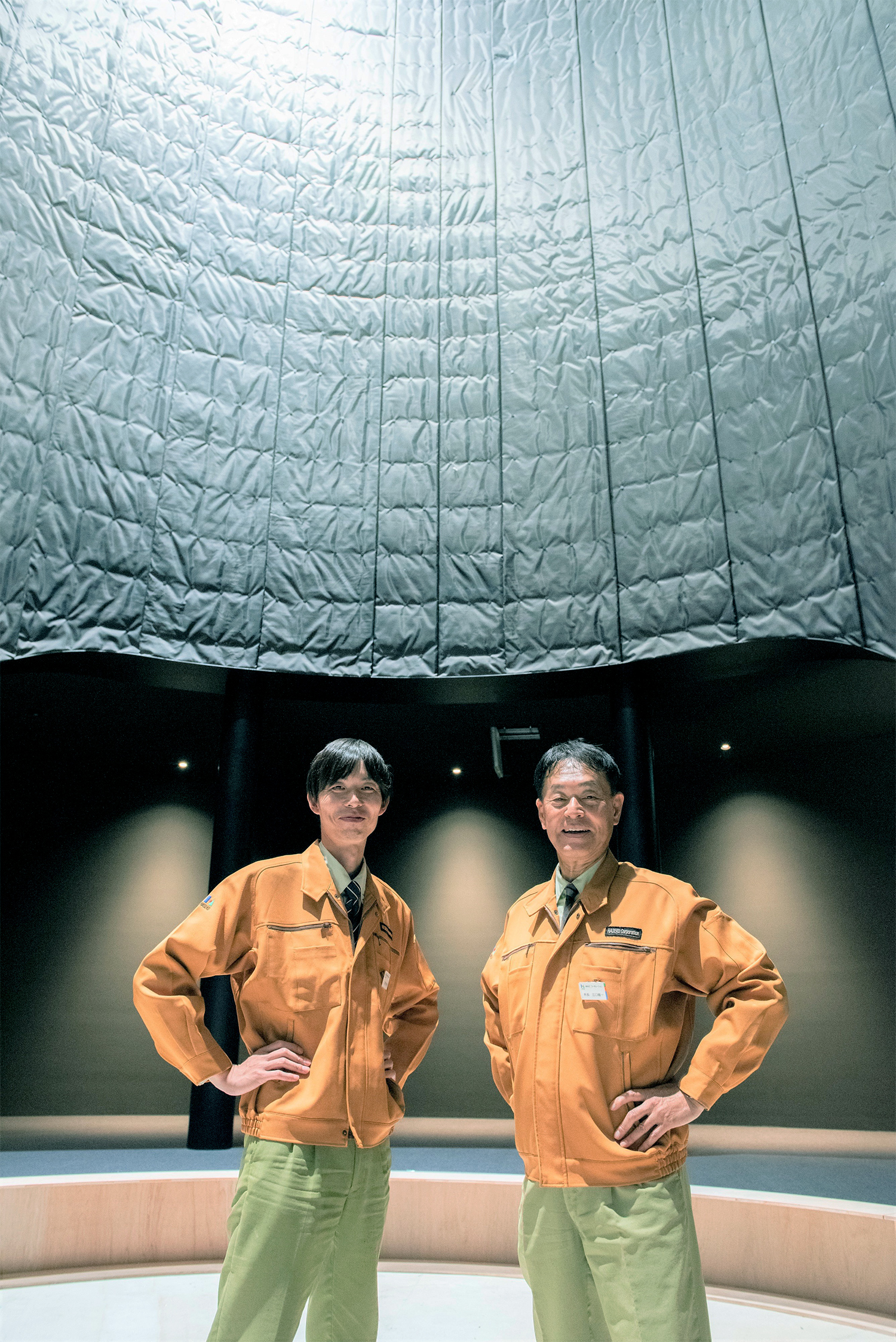

Tonomura recalled, “I was very happy when Professor Ishiguro stated that the best building in the Expo had been completed. There were many people within HASEKO who were surprised and asked us how we did it.”

Eguchi added, “When we handed over the building, there were stakeholders who shed tears of joy, and I also felt moved together with them, feeling glad to have worked hard on the construction. Actually, I was the only person in charge of directing construction management for the first four months after construction started. Subsequently, we had a major boost when Tonomura joined us, and I felt that I had really persevered and worked hard during that time. I also want to thank Tonomura again.”

“Within the company, there were words of praise, such as ‘This is amazing!’ and ‘Great job!’ What made me even happier was that Eguchi and Tonomura received an in-house award. It was the first time that a construction-related project received such an award. The two of them put in a lot of effort to complete the building with no incidents or accidents, and I think this will also help them in their future careers,” said Onishi.

This pavilion has a sense of presence even within the Expo’s venue, and seeing its completed state, emotions welled up in the three of them.

Eguchi commented, “I had completed many properties in my career so far, but this project gave me a different kind of emotion. What moved me the most was when I saw the pavilion lit up at night. It was different from the usual daytime look, and seeing the pavilion at night, which was only possible after completion, made me feel again that I had created an amazing building. Furthermore, when I saw the exhibits inside, it made me think again about what the houses of the future are for a company that offers condominiums.”

As for Tonomura, “I take pride in accomplishing a prominent building that, in a good sense, does not have the Expo flavor nor look flashy. HASEKO was not responsible for setting up the exhibits inside, and I was surprised to see how much the overall atmosphere could change with design when I walked around inside after the pavilion’s completion. While the construction of the building itself is important, it made me feel again the importance of things such as finishing and methods of display.”

“As someone who was involved for approximately three and a half years from the start of the project, I was deeply moved when I saw the completed pavilion. With general contractors who are well-known in Japan taking part in other pavilions, I had also believed that HASEKO could accomplish this task. However, given the characteristics of the Expo, there were areas where information disclosure—even within the company—was difficult. There were many times when it pained me that I could not give an answer when others innocently asked, ‘Can it really be done?’ Therefore, I also felt a great sense of relief that we could finally show the pavilion to others in HASEKO,” said Onishi.

Visit the pavilion and think about what it means to live

Lastly, the three of them had their messages for visitors to the Expo.

Tonomura said, “It is not limited to this pavilion, but I think there is no loss in visiting the Expo. You get to think about the future, be impressed by what you see, and things like that. Even if you don’t feel it now, in the future, the things you see and feel will become useful somewhere in your life. To those who are still hesitating, I strongly recommend visiting the Expo.”

“I think it is a pavilion that has left gaps for individuals to think about and ask questions. Personally, I was impressed by Zone 3, which imagines the world 1,000 years from now. That blending of sound, light, and android cannot be described with words. I really hope people will visit it and experience it for themselves. I also hope those who visit in daytime can stay around to see the nighttime lit-up pavilion, which begins in the evening,” said Eguchi.

From Onishi, “Instead of an unrealistic future, I think this is a pavilion that makes people—from children to adults—think about themes such as ‘What is life?’ ‘What does it mean to live?’ and ‘What does it mean to die?’ As these are themes where you may make new discoveries or change your thinking with each visit, I hope people will visit it several times if possible. Zone 2 shows scenes of the future 50 years from now, where you can see future products related to housing envisioned by our co-creation members. Please take a look at them. The contents of the Future of Housing Meeting organized by Professor Ishiguro, HASEKO members, and I have also been published in a book titled Do Androids Dream of Condominiums? Through the book, you can experience the vision of future housing, in terms of the importance of community, feasibility of integration with androids, and beyond nature. I hope people will read this book around the time of their visit to the pavilion.”

Interviewed: May 2025

[Profile]

Haseko Group

https://www.haseko.co.jp/hc/english//

Centered on the condominium business, including design, construction, sale, management, and repair, the Haseko Group offers housing and various housing-related services, from both aspects of systems and processes, for diversifying lifestyles, social issues faced by Japan, and changes in the social environment.